2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

Often in everyday life there are situations when this or that surface needs to be sanded, to remove the old coating of varnish or paint. It is very difficult to cope with this manually, especially with a large amount of work. Therefore, an electric sander is a must-have tool in the arsenal of any home craftsman. Depending on the correctly selected equipment and consumables, you can successfully solve a wide variety of tasks for the processing of various surfaces.

Principle of operation

This type of grinder is called so because a skin sheet is attached to the rollers of the tool, which looks like a closed belt. As the rollers rotate, the belt moves continuously. As a result of this movement, various surfaces are sanded quickly and efficiently. It is advisable to use a belt sander for processing large areas, since it has a high productivity. Modern mechanisms have adjustable belt speed.

How to choose the right one?

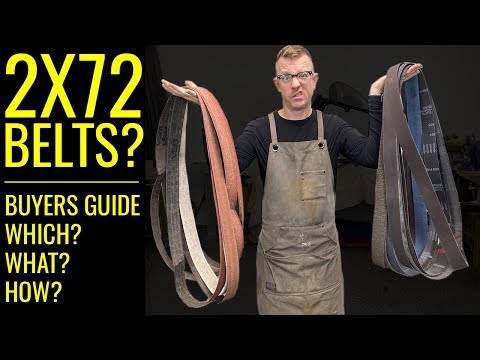

An abrasive belt is a fabric or paper backing on which an abrasive grain is attached with glue. It sticks together in a ring, which is why it is often called endless. To make the perfect choice, you need to carefully study the types of sandpaper bases, the properties of abrasive materials, have an idea of the length and width of the sanding belt, and also know what the grain size is.

Types of sandpaper basics

Sanding belt for a grinder is the most demanded abrasive. People call it a pelt, since earlier they used shark skins for grinding. It, like the tape, has its own base. It is worth taking a closer look at the most common skin bases.

- Paper . This is the most common and economical type of foundation. Such paper is impregnated with polymers to impart strength and resistance to abrasion or tearing. But it is not recommended for intensive use.

- Textile . It is an elastic base that easily conforms to the shape of the product. It is more stable, it has a long service life, but the abrasive can crumble when pulled. The fabric base of the skin is durable and resistant to moisture. It is used for intensive work with various types of wood.

- Fiber . It is used for processing hard materials.

- Combined . It is a combination of cloth and paper that has been coated with abrasive. This base combines the beneficial properties of paper and fabric. It is resistant to bending, abrasion and moisture. Such a base is expensive.

Abrasive properties

As you know, abrasive materials are characterized by high hardness and are used for surface treatment of various materials. Harder abrasive grains are recommended for deeper cutting. If you arrange the abrasive grains in decreasing hardness, you get the following chain: diamond - garnet - quartz - aluminum oxide - silicon carbide - electrocorundum. The abrasive is applied to the substrate in several ways.

- Open fill . With this method, 60% of the base surface is covered. Recommended for soft materials with low density, it prevents clogging of gaps and the formation of lumps.

- Closed fill . 100% of the base surface is covered. This method is essential when sanding metals and hardwoods.

Dimensions (edit)

When choosing a tape, you must carefully study the parameters of its length and width. If the belt is wide, the power of the belt sander is higher and the travel speed is slower. When using a narrow belt, the power of the mechanism is low and the rotation speed is high. The ideal choice would be tape sizes of the following standard:

- width 75 (76), 100 or 115 mm;

- length - 457 or 533 mm.

Important! When choosing the width, you should take into account the working conditions, and the efficiency depends on the length.

Grain

The quality of processing of any surfaces will depend on this property. If the grit size of the abrasive material is higher, then the treatment is softer. The grain size is usually denoted by the English letter P. It corresponds to a numerical range from 12 to 2500. The larger the number, the finer the abrasive. There are several types of coarse belts.

- Very large . Such tapes have especially coarse grains (P22 – P36). They are necessary for rough grinding of surfaces and their leveling.

- Large . Tapes with P40 – P60 index. They are required for the initial processing of the material, they are not clogged with dust due to the coarse grain size.

- For initial processing . Tapes marked P70 – P120 are recommended for removing paint and varnish or rust.

- For final processing . Tapes with P150 – P220 index. With their help, they clean the surface before polishing.

Fine-grained belts also come in several types

- For finishing . They are recommended for the final sanding of hardwoods. Their grain size is P240 – P280.

- For polishing . These tapes make painted surfaces smooth but can become clogged with dust and paint. Their grain size is P400 – P600.

- For fine sanding . P1000 belts are ideal for finishing metal, ceramic or varnished wood.

When choosing belts for a sander, be sure to study the requirements of the tool and the parameters of the specific material. A high-quality sanding belt will last you a long time, even with frequent use.

Recommended:

Mounting Belt (36 Photos): A Five-point Safety Belt For Work At Height And Other Safety Models. How Should An Installer's Belt Be Stored?

The assembly belt is the most important element of protective equipment for work at height. What are the mounting straps? Strapless, strapless, five-point harness and other safety models. GOST requirements. How to choose and store an installer's belt?

Walk-behind Tractor Belt: How To Tighten And Adjust The Belt Correctly? Dimensions And Adjustment Of The Toothed Belt On The Walk-behind Tractor

If the belt for the walk-behind tractor is selected, installed, tensioned and adjusted correctly, then the device will cope with all the tasks assigned to it. Learn how to tension and adjust the belt correctly with your own hands

Sanders Makita: Features Of Belt And Eccentric Sanders. How To Choose Pneumatic And Vibration Machines For Wood And Concrete Work?

Makita sanders are very diverse in their design and operating principles. How to choose the right model? What features of belt and eccentric sanders can affect the work result? How to choose pneumatic and vibration machines for wood and concrete work?

Tool Belt: Choose A Construction Belt Bag For The Installer, Electrician And Carpenter. How To Make A Do-it-yourself Unloading Belt?

A tool belt is a must for electricians and high-altitude workers. How to choose the right construction waist bag for the installer and carpenter? Can you make it yourself?

Belt For The Neva Walk-behind Tractor: The Size Of The Drive Belt For The "MB-1" And "A-49" Walk-behind Tractor. How To Tighten The Looper Belt? Length And Markings Of The V-belt

Belt for the Neva walk-behind tractor: the size of the drive belt for the "MB-1" and "A-49" walk-behind tractor. How to Tension the Looper Belt? Length and markings of the V-belt. How to choose the right belt?