2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

Recently, the manufacture of awnings near the house has become quite popular. This is a special uncomplicated structure, with the help of which you can not only hide from the scorching sun and pouring rain, but also improve the surrounding area.

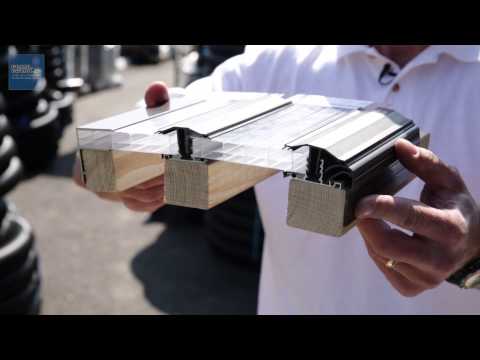

Previously, for the manufacture of awnings, massive materials were used, for example, slate or wood, which visually made the building heavier and caused a lot of trouble during the construction process. With the advent of lightweight polycarbonate on the construction market, it has become much easier, faster and cheaper to erect such structures. It is a modern building material, transparent but durable. It belongs to the group of thermoplastics, and bisphenol is the main raw material for its production. There are two types of polycarbonate - monolithic and honeycomb.

What thickness of monolithic polycarbonate to choose?

Molded polycarbonate is a solid sheet of special plastic that is often used to equip sheds. It is often referred to as “impact resistant glass”. He has a number of positive qualities. Let's list the main ones.

- Strength. Snow, rain and strong winds are not afraid of him.

- High coefficient of resistance to aggressive environment.

- Flexibility. It can be used to make canopies in the form of an arch.

- Excellent thermal conductivity and thermal insulation performance.

Monolithic polycarbonate sheet is characterized by the following parameters:

- width - 2050 mm;

- length - 3050 mm;

- weight - 7, 2 kg;

- the minimum bending radius is 0.9 m;

- shelf life - 25 years;

- thickness - from 2 to 15 mm.

As you can see, the thickness indicators are quite diverse. For a canopy, you can choose absolutely any size, the main thing is to take into account several basic criteria and factors. Among them, the load and the distance between the supports, as well as the size of the structure, are important. Usually, when choosing the thickness of sheets of monolithic polycarbonate for a canopy, it is the last factor that is taken into account, for example:

- from 2 to 4 mm - used when erecting a small curved canopy;

- 6–8 mm - suitable for medium-sized structures that are constantly exposed to heavy loads and mechanical stress;

- from 10 to 15 mm - they are used quite rarely, the use of such material is relevant only if the structure is subject to high loads.

How thick should the honeycomb material be?

Cellular polycarbonate consists of several thin plastic sheets connected by jumpers that play the role of stiffening ribs. Like monolithic, it is also very often used in the process of building sheds. The physical and technical parameters of cellular polycarbonate, of course, differ from the characteristics of a monolithic one. It is characterized by:

- width - 2100 mm;

- length - 6000 and 12000 mm;

- weight - 1, 3 kg;

- the minimum bending radius is 1.05 m;

- shelf life - 10 years;

- thickness - from 4 to 12 mm.

Thus, cellular polycarbonate is much lighter than a monolithic type, but the service life is 2 times less. The length of the panel is also significantly different, but the thickness is about the same.

It follows from this that the cellular version is advisable to use for the construction of small-sized sheds with a minimum load level

- Sheets with a thickness of 4 mm can be used for the construction of small sheds , which are characterized by a significant radius of curvature. For example, if a roof is needed for a gazebo or greenhouse, it is better to choose a material of just this thickness.

- Sheet of material with a thickness of 6 to 8 mm are used only if the structure is subject to a constant heavy load. It is suitable for building a pool or car shelter.

The sheet with a thickness of 10 and 12 mm can only be used in extreme climatic conditions. Such awnings are designed to withstand strong gusts of wind, heavy loads and constant mechanical stress.

How to calculate?

For the construction of a canopy, both monolithic and cellular polycarbonate are suitable. The main thing – make the correct calculation of the maximum possible load on the material, and also make sure that the technical parameters of the sheet meet the requirements . So, if the weight of the sheet is known, the weight of the entire polycarbonate roofing can be calculated. And also to determine the thickness of the sheets, the area, design features of the canopy, technical calculations of the loads are taken into account.

There is no single mathematical formula for determining the required thickness of polycarbonate for the construction of a canopy. But in order to determine this value as closely as possible, it is necessary to use the following regulatory document like SNiP 2.01.07-85 . These building codes will help you choose the right material for a specific climatic zone, taking into account the structure of the sheet and the design features of the canopy.

If it is not possible to do this on your own, then you can consult with a specialist - a sales consultant.

Recommended:

Which Polycarbonate To Choose For A Greenhouse? Which Thickness Is Better: 4 Mm Or 6 Mm? Choice Of Density, Color And Manufacturer Of High-quality Polycarbonate

By what criteria, and what kind of polycarbonate is better to choose for a greenhouse? What material thickness of 4 or 6 mm is more suitable for different types of garden structures? What exactly is the secret of choosing the right density for polycarbonate?

Which Polycarbonate To Choose For A Greenhouse? How And Where Is It Better To Use A Material With A Honeycomb Structure 4 Mm Thick And What Density Should Be, Reviews

Cellular polycarbonate is a demanded and high-quality material used as a covering material when arranging greenhouses. Which polycarbonate should you choose for your greenhouse?

Which Polycarbonate To Choose For A Canopy? What Is The Best View For A Gazebo? What Thickness Should You Use? Should I Take Cellular Polycarbonate?

Which polycarbonate to choose for mounting a canopy - monolithic or cellular? What is the best view for a gazebo, car park and greenhouse? What thickness of polycarbonate should you use and what color should you prefer?

Which Foundation Is Better: Pile Or Tape? Which Is Cheaper And Which Is More Expensive, How To Choose The Right One, Differences In Designs On Screw Piles And Tape, Reviews

Pile or tape - which foundation is better? What are the characteristics and benefits of pile and tape options? Which type of foundation is cheaper and which is more expensive? How to choose the right type of base based on the type of soil on which construction is planned?

The Thickness Of The Corrugated Sheet For The Fence: Which Is Better To Choose And What Should Be The Thickness Of The Corrugated Board? Optimal Options For A Fence With A Height Of 2 Meters

What does the thickness of the corrugated sheet for the fence affect? In this article, we will consider the standard options. What is the best thickness? Depending on the material used, what should be the thickness of the corrugated board?