2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

The gutter for paving slabs is laid together with the main coating and is used to remove accumulated rain moisture, puddles from melting snow. According to the type of material, such gutters can be plastic and concrete, with or without a grid. It is worth learning more about the installation features, dimensions and other nuances of the choice of gutters before laying paving stones or tiled covering in the yard.

Requirements

The gutter for paving slabs is a gutter that runs along the paved area. It serves as a tray for collecting and draining water, it can be operated independently or in combination with the general drainage system on the site.

Let's consider the basic requirements for such elements

- Form . Semicircular is considered optimal; in storm sewer systems, trays can be square, rectangular, trapezoidal.

- Installation level . It should be slightly below the base cover to allow drainage and collection of water.

- Laying method . Drains are arranged in the form of a continuous line of communications in order to exclude the ingress of water into the ground.

- Gutter diameter . Its size should be calculated based on the amount of precipitation in the region, and other factors. For example, if you regularly wash your car with a hose in a parking lot, it is better to give preference to a deeper gutter.

- Place of installation . It is chosen taking into account the maximum outflow of water.

When installing the gutter, the harmony of the design solution is often overlooked. In some cases, it should be given more attention. For example, find an option to match the tiles or choose a gutter model with a beautiful decorative grid.

Views

All sidewalk gutters can be divided into several types according to the materials used in their manufacture. There are several of the most common options.

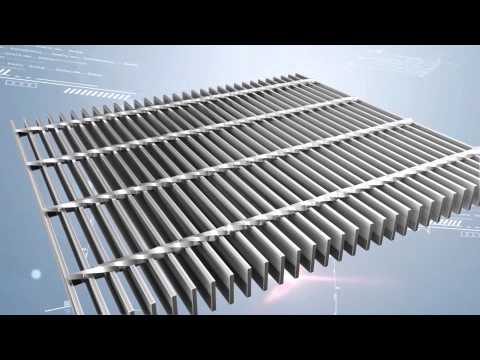

Metal … It can be made of black or galvanized steel, painted, coated with protective materials, including polymer type. Metal gutters are practical, durable, and can withstand significant loads. They do not create significant pressure on the surface of the base, they are repairable.

Plastic … A universal option for the urban environment and the improvement of private territories. Differs in simplicity of installation, ease of transportation. Polymer materials are not afraid of corrosion, noise during their operation is completely excluded. Plastic gutters are available on the market in a wide range of sizes, shapes, colors and designs, and their lifespan is virtually unlimited.

Concrete … The most difficult option, but the most reliable, durable, quiet. It goes well with paving slabs made of concrete and stone, completely waterproof, not afraid of thermal effects. Concrete trays are best placed in areas with increased operational loads.

And also all trays for water drainage are classified according to the degree of their depth. Allocate surface open systems in the form of a gutter, as well as options with a grid for installation under the level of the covering. The second option is usually used on sites with a laid storm sewer.

The role of the lattice is not only decorative - it protects the drain from clogging, prevents injuries when people and pets move around the site.

Nuances of choice

When choosing gutters for gutters, the main criterion is the size of the profile of such structures. There are certain standards governing their installation and purpose.

- Drainage channels with a profile depth of 250 mm . They are intended for highways, public areas with a carriageway width of 6 m or more. Such a gutter comes with a grating made of concrete and metal.

- Gutter with a wide profile of 50 cm … It is installed on footpaths and other areas with heavy traffic.

- Profile with a depth of 160 mm and a width of 250 mm … This is the best option for private households. A gutter of this type is well suited for laying along the blind area, on sidewalks up to 2 m wide, for removing moisture from garden paths and courtyards.

The color scheme is also selected individually.

For example, galvanized and chrome-plated trays with grates work well for a high-tech house. A classic concrete building with a blind area will be complemented by concrete gutters without staining. Bright polymer trays can be selected to match the color of the roof moisture collection system, as well as to match the window frames or porch trim.

How to install?

The installation of a drain for paving slabs is always carried out at an angle of 3-5 degrees, since such systems provide for a gravity drainage of the incoming fluid. The slope is reduced as you get closer to buildings, and the slope is increased along the paths and in other long sections. If the thickness of the gutter and the tiles match, they can be laid on a common base. With a deeper laying, it will be necessary to first prepare a concrete platform 10-15 cm high in the trench.

On a private territory, the gutter is usually laid on sand or a cement-sand base without concreting. In this case, all work is performed in a specific order.

- Site formation with excavation.

- Geotextile laying.

- Backfill with a layer of sand 100-150 mm thick with tamping and wetting with water.

- Laying crushed stone cushion 10-15 cm. Leveling.

- Installation of perimeter curbs on concrete mortar. The horizontal level is necessarily measured.

- Backfill of dry cement-sand mixture in a ratio of 50/50. From above, gutters are laid close to the curbs, then tiles in rows.

- The finished coating is thoroughly watered with water, the places where the trays are installed, too. The gaps are filled with unused sand and cement mixture. The excess is cleaned off.

At the end of the work, the surfaces are watered again, left to cure … Such dry concreting is much easier and faster than the classical one, and the bond strength is high.

Recommended:

Large Paving Slabs: Large-format Slabs 500x500 And Other Sizes. Large Square, Rectangular And Other Tiles. Styling

Where is large paving slab used and what are its features? What are the advantages of large tiles? Large-format slabs 500x500 mm and other sizes. Varieties of such material. How are large square and rectangular tiles laid?

Paving Stones (61 Photos): How Is It Different From Paving Slabs? What It Is? Production And Types, Gray, Brown And Other, Choice Of Full Chipped And Other Paving Stones

Paving stones: what is it and how is it different from ordinary paving slabs? Production technology and features of various types of paving stones. Gray, red or luminous: how to choose the color and layout of paving stones for a summer residence and a country house?

Plastic Paving Slabs: Paving Stones And Other Plastic For Paths, Production. How To Do It Yourself? 500x500x50 And Other Sizes

What are plastic paving slabs, paving stones and other plastic walkway tiles? How is the production of plastic paving slabs carried out? We tell in our publication

Concrete Paving Slabs: Paving Stones, 500x500x50 And 300x300x30, Gray And Other Colors, Reinforced Concrete Slabs, Smooth And Others

What are the concrete paving slabs by purpose and shape? What are the advantages of concrete slabs? What are the dimensions of 500x500x50 and 300x300x30 mm suitable for? What is remarkable about paving stones, and where is it better to use it, gray and of a different color?

Granite Paving Stones (33 Photos): Paving With Granite Paving Slabs, Chipped And Other Paving Stones, Laying Technology, Tiles 100x100x50 And Other Sizes

Granite paving stones - laying material. What are the pros and cons? What are the features of chipped and other paving stones? What is the styling technology? Where is paving with granite paving slabs used?