2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

Wall decoration is a mandatory step in any construction. The main requirements for the finishing material are durability and practicality. These are the qualities that PVC panels have.

These products can be used both outside and inside buildings . But in order for them to serve for a long time and reliably, they should be correctly mounted. Therefore, a special auxiliary profile is used for such purposes. It allows you to securely fix the canvases, regardless of their direction and location.

Peculiarities

Decorating walls with PVC panels is often practiced today. This is due to the fact that the material is well processed and is not afraid of moisture. Fastening of such products is carried out on a previously prepared frame. This design is supplemented with a special mounting profile. Outwardly, these products look different, depending on the purpose of the structure.

With the help of such a profile, several basic tasks are solved at once

- Giving additional strength to the structure. This is important if the systems are installed outside the home. Correctly closed slots will prevent large amounts of moisture from entering and also minimize the risk of wind exposure to the panels themselves.

- Creation of a decorative effect. It is impossible to grind the panel joints perfectly evenly, which leads to the formation of gaps. Therefore, the profile helps to hide these imperfections, creating a unique external architecture of the structure.

The profile for PVC panels is made from various materials

- Plastic . This type of product is quite common. Differs in durability and ease of installation. It should also highlight the low cost of products, which led to such a wide distribution. This profile is almost always used for interior work. Plastic is easy to paint, which allows you to give it different shades. But the most common color is white.

- Metal . The metal profile is much less common. The material is durable and unique in design. Aluminum or steel structures are easily resistant to external climatic influences. But with plastic panels, it is only used to create durable or designer surfaces.

Some manufacturers can give the profile a color according to the customer's order. Thus, these building structures can be easily supplemented with the basic design of a room or façade.

Views

The profile is one of the main elements for the installation of plastic panels. Its application allows you to quickly and efficiently align all the elements in the plane you need. But the surface of the walls or ceiling is not always perfectly flat.

Therefore, for the organization of such systems today, several types of profiles are used

- U-shaped . These constructions are also called starting constructions. They are installed before starting installation work on each wall. The products are intended for covering the ends of the panels. They are often attached around the perimeter of doorways or window frames. The size of these products can vary over a wide range (10 mm, 12 mm, etc.).

- F-shaped . Technically, these elements are installed in the same places as in the previous version. But here such a profile can be more called finishing, since its use gives a decorative finish to the structures after their installation.

- H-shaped . A profile of this type is distinguished by the presence of two internal grooves on opposite sides. It is a connecting piece and is used when it is necessary to supplement one lamellae with another. This occurs when the panel is not long enough to completely cover the wall of the house. Docking profiles are the most versatile and often in demand.

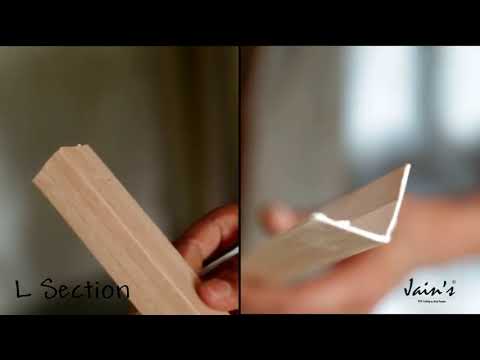

- Corners . These elements are installed at the joints of two panels. Docking corners are of several types: external, internal, decorative and universal. The shape of this profile is completely different. Some products are equipped with multiple grooves, which allows them to be used in different types of corners.

Corner sizes can vary from 10x10 mm to 50x50 mm. Particular attention should be paid to universal products. To use them in a certain plane, you just need to bend the structure in the direction you want. But at the same time it is impossible to apply them repeatedly to solve various problems.

All corners are also equipped with special grooves where the panels can be placed at a certain depth. With the help of such structures, you can get a perfectly flat vertical surface without distortions.

- Skirting boards . They are not classic profiles. They are used to close the joints between panels near the floor. This allows you to create a smooth transition while decorating the surface. They are made in most cases from plastic. There are many modifications on the market that differ in design and practicality.

- Reiki . Structures are used to create support elements. They can be supplemented with various fastening systems. They are not used as often as they are not required elements.

All types of profiles can be plastic or metal. In most cases, aluminum is used, but there are other types of products. This allows you to match items to suit your design.

How to choose the right one?

The profile for PVC panels is used quite often. There are many modifications of such products on the market today, but all of them are intended to solve a single problem.

There are several factors to consider when purchasing this product

- Profile view . Here it is important to consider only the place where this product will be used. If you need to veneer only a part of the surface without corners and openings, then you only need the starting elements that will be located around the perimeter. Sometimes you will need decorative overlays.

- Design . Pay particular attention to the color of the material. Today, many companies produce white profiles that suit a variety of interior styles. But if you need colored items, then they can be found in various specialized stores or purchased on order.

- Material . Manufacturers do not offer much choice here. In most cases, you have to choose between metal or plastic. It is important to analyze only the quality of the product itself. If you plan to use a plastic profile on the street, then you need to give preference to one that can withstand frost without losing its strength characteristics.

- Technical specifications . Special attention is paid here only to the width of the groove where the plastic panel will enter. Do not use a profile that is too narrow, as it may become unusable over time. The width of the groove is almost always standard, since all panels are produced under the same standard size.

If you have purchased non-standard modifications of the strips, then you must definitely check whether the profile is suitable for them.

Installation

Installation of a profile for PVC panels is not a difficult task. Almost anyone can handle it. Before attaching the guides, there are several preparatory steps should be performed.

- Leveling the surface . Initially, the walls or ceiling are analyzed for damage. If the surfaces have large cracks or drops, it is advisable to eliminate them with the help of special mixtures. This is important if the panels in the future are planned to be fixed directly on top of the wall without additional frames.

- Construction of the lathing . Even a wooden frame is suitable for plastic panels, which can easily support the weight of these products. But you can also construct it from special metal structures.

The profile fixing algorithm consists of several sequential steps

- Installation of starting elements . They are located along the perimeter of the finishing surface (ceiling, wall). It is important here to place opposite structures in such a position that they are in the same plane. If this is not done, then a distortion may occur, which will affect the panels themselves and their decorative appearance. Fastening of starting profiles is carried out using brackets or special self-tapping screws. Here it is important to correctly align them horizontally and vertically. The installation of panels in the future depends on this.

- Installation of corner elements . In this case, both internal and external elements are used. In most cases, they can act as starting points. You can fix them according to the same principle as the previous type.

- Fastening of internal intermediate profiles . Systems of this type are installed on walls that are too long, where it is impossible to find the right panel size.

Plastic panels can expand or contract with temperature changes. Therefore, it is necessary that when installed in a profile, a small gap remains between the wall and the material. It is advisable to take it into account when designing the entire system. Before fixing all profiles, it is advisable to choose the direction of laying the sheets.

During the installation work, you need to carefully measure in order not to get errors . This is especially important for the guide and intermediate profile. If you need to mount several reference lines with such structures along the wall, then it is better to do it sequentially. Not every experienced specialist can do this right away.

Please note that you can attach the profile not only with staples, but also glue it to the base. This is especially often practiced with plastic elements that are easily fixed with various polymer compounds.

When the frame is formed from the profile, you can start installing and fixing the panels. The installation technology is selected individually and depends only on external conditions. In most cases, you just need to insert the end of the product into the profile groove. The panel is then leveled and nailed or glued to the frame.

Profile for PVC panels are versatile products that allow not only to speed up installation, but also to extend the service life of the entire system. It is very important to select them for a specific structure mounted on the ceiling or walls. In addition, in order to obtain a durable and durable surface, it is advisable to trust all installation work to experienced and proven specialists.

Recommended:

How To Fix PVC Panels To A Wall Without Lathing? How To Fix Plastic Panels To Liquid Nails? Can I Attach Them To The Ceiling With Self-tapping Screws?

PVC panels are not a new building material for wall and ceiling cladding. However, the demand for them has increased relatively recently. PVC material is easy to work with, does not require special knowledge of installation. But not everyone understands how and how to fix these plastic plates. How to fix PVC panels to a wall without lathing? How to fix plastic panels to liquid nails?

Docking Profiles: For Joining Laminate And Tiles, Aluminum And Flexible Flooring Profiles, Liquid Profiles For Joining Linoleum And Laminated Chipboard

Docking profiles - what they are, what they are, how they are mounted. Features and types of construction. Profiles for laminate and tile joints, aluminum and flexible for flooring

Installation Of PVC Panels On The Wall (65 Photos): How To Fix Lamellas And How To Sheathe The Wall, Decoration And Sheathing With Plastic Panels, Mounting Options

Installation of PVC panels can be done by hand. How to fix plastic slats and how to sheathe the wall with them? How to choose high-quality panels for finishing floors and what are the pros and cons they have?

Installation Of PVC Panels (81 Photos): How To Fix And How To Glue, Finishing The Interior Surfaces Of The Room And Installing Plastic Panels, Mounting Options

It is quite possible to install PVC panels with your own hands. What are their advantages? How to fix the panels to the lathing and how to glue them to the concrete surface? Which manufacturer should you give preference to when buying?

Starting Profiles For Panels: Guide Strips For PVC Panels 8-12 Mm And Others, Made Of Plastic And Metal Strips. How To Attach The Starter Profile?

All about starting profiles for panels. Features of the guide bar for pvc panels 8-12 mm and other sizes