2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

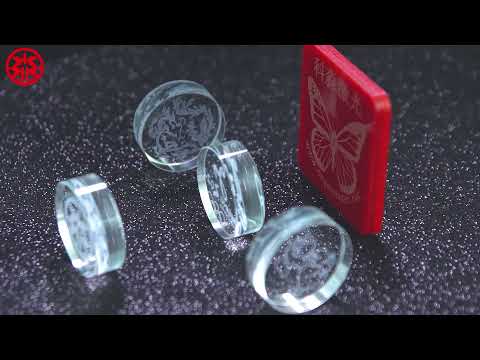

For many decades, along with the industrial production of consumer goods, various types of crafts have been successfully applied and improved, the task of which is not only to create products, but also to decorate them. In recent years, decorative engraving on plexiglass has become increasingly popular. Design patterns can be seen both on household items and on advertising structures. Thanks to innovative developments and modern equipment, specialists in this industry create unique patterns in any stylistic direction.

What it is?

Plexiglass engraving is one of the modern types of painting, which involves applying a decorative pattern to different types of glass surfaces. This technology is considered a young art and has existed for only a few decades - despite this, it has already become popular and in demand. This method can be used on the following types of surfaces:

- mirror;

- crystal;

- sheet;

- polished;

- pressed;

- cast;

- tare.

Modern specialists use several methods of engraving, which depend on the following factors:

- raw material;

- the complexity and volume of the pattern;

- the need for detail.

Most popular engraving methods:

classical - standard engraving method;

interior - creating a pattern inside the canvas using two lasers;

small engraving - the size of the pattern is limited to a range of 100x100 mm;

3D technology , with which you can apply a volumetric pattern inside the glass sheet;

diamond - the way vector images and texts are applied.

Design

The wide field of application of engraved products makes designers look for new solutions for a more effective presentation of the image.

Large laser drawings go well with illumination, which can be placed in various parts of the composition, and the color spectrum of the rays depends only on the wishes of the customer, as well as on the stylistic direction of the composition.

The pattern on frosted glass looks expressive and unique . This combination is in high demand when decorating table sets, which often use a combination of convex and sunken lines.

Some decorators give their creation the desired color shade with the help of special paints that are applied to the selected fragments.

Applications

Due to the huge technological capabilities in the creation of various decorative patterns, engraving can be seen both on decor and household items, and on advertising structures. Most often, engraved patterns can be seen on the following items:

- automotive glass;

- lamps;

- interior items;

- glass parts of doors;

- glass cutlery;

- photo frames and glass paintings;

- decorative souvenirs;

- prize items, cups and medals.

Recently, more and more orders for specialists have been received for decorating signboards, name plates and advertising items, the effect of which can be enhanced by installing additional lighting. Beams of light striking the engraved lines are refracted at different angles to create a dramatic glow.

How to do it?

Modern technological progress provides for both an industrial method of engraving, and the possibility of doing it yourself at home.

To decorate products, large enterprises use special machines, which, according to a set program, use a CNC laser to burn out a given pattern . Due to the high temperature conditions and software accuracy, all lines have clear and even outlines. The laser engraving method can also be used at home, however, the purchase of a special machine requires large financial investments and professional skills of the master, who must undergo both theoretical and practical training.

Advantages of laser engraving:

- pattern thickness no more than 0.01 mm;

- the ability to create patterns of any complexity;

- high quality of work;

- drawing a pattern both on flat surfaces and on convex ones;

- full automation of the process.

At home, most craftsmen use the following types of tools:

- electric dremel;

- engraver (drill).

Regardless of the method chosen, there are several techniques for applying the pattern

- Graphics editor - a program that allows you to transfer an image to film. The resulting image just needs to be fixed on the working surface.

- Plotter - a device for accurate construction of layouts.

- Marker - a device that leaves clear lines on the glass. You can apply a drawing either independently or by redrawing a sketch.

To prevent the appearance of defects and damage to raw materials, as well as breakdown of working equipment, novice craftsmen should carefully study the recommendations of specialists before starting work:

- work of the engraver only at low speeds, which will prevent excessive melting of the pattern and the appearance of uneven edges;

- regular cleaning of glass sawdust with special brushes;

- mandatory setting of the line depth limiter, which will help to get a clear and uniform pattern;

- creation of a drawing only according to a pre-applied stencil;

- exact selection of the required nozzle;

- obligatory trial engraving on a small workpiece.

It is strictly forbidden to use rags to clean the glass during operation, contact with the glass of which may lead to dullness of the working surface.

To protect the eyes and skin, it is imperative to use personal protective equipment.

Recommended:

Greenhouse Lamps: Infrared And LED Greenhouse Lamps, Which Ones To Choose, Lighting With Sodium Lamps And Daylight Lamps

Lamps for greenhouses must be chosen taking into account all the recommendations. How to choose infrared and LED greenhouse lights for your greenhouse? How to choose lamps for a home or country greenhouse?

Vintage Lamps: Loft Style And Other, LED Lamps, Ceiling And Other Lamps. Vintage Chandeliers And Lamps In The Interior

Vintage lamps have their own characteristics, but are suitable for almost any interior style. Vintage LED lamps are suitable for styles: classic, loft, retro and other styles, bringing zest and beauty to the interior. Lighting sources are very different: ceiling, tabletop, LED - you will learn about all the options from the article

Backlight For TV: Choose LED Strip And LED Lamps For TV 32 Inches And Other Sizes

Why do I need a TV backlight? Choosing an LED strip and LED lamps for a 32-inch TV and other sizes. Is it possible to make a backlight with your own hands?

DIY Phytolamps: How To Make LED Plant Lamps? Master Class On The Manufacture Of LED Lamps. Features Of Setting The Backlight

Plants, in addition to moisture and fertilizers, need light for normal development. When growing flora indoors, it is often not enough. Phytolamps will help to correct the situation. How to make LED plant lamps with your own hands. How do different light spectra affect plants?

Stichel: For Metal Engraving And Wood Carving, A Set For Hand Engraving, Electric Stitches And Other Tools. How To Draw A Drawing?

What is a graver for metal engraving? Why is it necessary to test the tool before purchasing in metal carving (as well as in wood)? What kind of gravers can be in a set for hand engraving?