2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

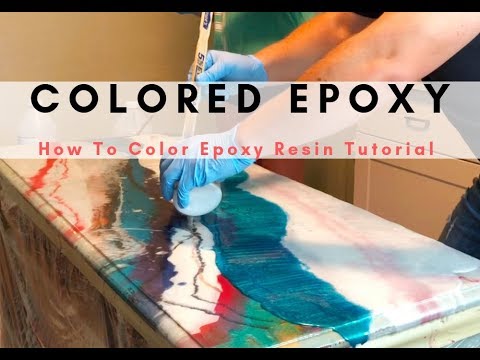

In recent years, the field of use of epoxy has expanded significantly. If earlier it included mainly the repair and construction sphere, now the material is widely used in mechanical engineering and shipbuilding, resin serves as a basic component in the production of furniture, the manufacture of all kinds of jewelry and bijouterie is considered a relatively young direction. That is why the question of coloring the composition is increasingly arising. In this article, we will look at the main ways to give epoxy different shades.

The need for application

The epoxy itself is crystal clear. This allows you to give it the most original colors, create a spectacular shine and achieve color transitions.

For products used outdoors, this issue is especially relevant . The problem is that ultraviolet rays have a destructive effect on this material. A characteristic sign of a violation of bonds within the epoxy is its turbidity. The application of LCI allows you to postpone this process for a long time.

The coating must be renewed regularly, the frequency of treatment is calculated taking into account the time spent in the sun, the intensity of the action of sunlight and the characteristics of the enamel used.

In some situations, a more practical solution would be to give the necessary shade even at the stage of manufacturing the elements . This practice is effective if the materials are used inside the dwelling, when the negative effects of the sun's rays are completely neutralized.

Main characteristics

When choosing permanent paints for external resin coating, preference should be given to two-component epoxy and two-component polyurethane compounds. The use of alkyd enamels (oil paints) is also allowed.

When choosing, you should also take into account the following factors

- Alkyd and epoxy paints They are characterized by extremely low resistance to ultraviolet radiation, so they do not need to be used for outdoor work, as well as for painting surfaces that are planned to be used outdoors.

- Higher quality polyurethane paints . However, they are laborious to apply - the coating forms a glossy coating, any, even the slightest flaws will be noticeable on it. Nevertheless, polyurethane enamel is wear-resistant, resistant to UV radiation, and retains its performance characteristics under the influence of moisture and other external factors. Of the shortcomings, only the high cost can be distinguished.

- Alkyd enamels are cheap , they are not picky in application, they can be painted with epoxy with a brush, as well as with a roller or spray. This coating easily hides minor defects, but the enamel dries for a long time.

Tip: for protection from exposure to sunlight, it is better to give preference to opaque dyes.

Before starting work, be sure to do a little test. For this paint must be applied to a small fragment in an inconspicuous place and see how the result is obtained . To make sure that the coating is dry not only on the outside, but also on the inside, you can try to pry it off with your fingernail.

When making items used indoors, it is better to give preference to special dyes. They are added to the resin prior to starting work.

Coloring can be one-color, with glitter, mother-of-pearl or luminescent . If you introduce a drop of dye into epoxy resin, you get a beautiful translucent sheen. For a more intense color scheme, you must first paint the resin white, and only then re-tint with colored paint.

Species overview

Coloring pigments are presented in a wide variety, most often in the form of a concentrated paste or powdery powder.

Monochromatic

Pigment paste is used for single-color dyeing . This material is characterized by high hiding power, the increased concentration of the active substance allows you to use the paste economically - even the smallest can with frequent use can be enough for a long time.

The advantages of pastes include high speed and ease of mixing, as well as the fact that they completely eliminate the risk of pigment lumps. In this way, the paste compares favorably with other colors.

Staining can be done in white, black or color . The pigment concentration is set taking into account the desired color saturation. For example, if you add more paste, you can get a darker shade. In any case, the maximum paste ratio should not be higher than 10-15% of the total resin volume.

Nowadays, stores offer the widest assortment of pastes in a wide variety of price ranges. If you wish, you can mix several colors and get a new tone yourself.

With phosphor

Fluorescent powders with phosphor are of organic origin. This composition absorbs and accumulates ultraviolet rays, and with the onset of darkness it slowly releases the accumulated energy . Due to the introduction of special components, the color can be neon colored or colorless. Green is most often used - in daylight this color has a pale green tone, and in the dark it gives a fairly bright neon glow.

The rich color and intensity of highlighting directly depends on the material into which the powder is injected . This substance is absolutely safe, does not contain toxic components, and therefore does not cause harm in contact with the skin. It is added in a small volume, the prepared resin is mixed and applied to the surface.

Matte

With some types of finishes, it becomes necessary to create matte surfaces. For this, special pigments are used, which contain components that neutralize gloss. In such cases, matting dyes are used.

Mother of pearl and metallic

Metallic pigments are available in several varieties:

- gold;

- silver;

- copper;

- pearlescent filler.

The structure of the color is a fine powder without introducing any foreign particles. It belongs to the category of professional dyes and has a high cost.

The main advantage of this composition is its economical consumption. We pay special attention to the fact that there are a large number of fakes on the market - in this case, some other particles are present in the powder, which significantly worsens the final quality of coloring.

Gold pigment gives objects a noble shade . Experienced craftsmen often use a burner in their work, it acts as a color enhancer. To do this, you need to hold the burner under the pigment at a distance of 10-20 cm, the pigment then floats up, and then you can make shimmery stains.

The silver composition has similar properties, which gives a silvery shimmer . When a small amount is added to a transparent epoxy, the staining result can be truly amazing and unusual. This effect is used when decorating design objects, as well as when creating paintings.

Bronze powder produces a metallic resin with an even shine reminiscent of copper . The end result directly depends on the proportions used. Metallic pigments are added to the liquid resin to achieve the result.

The mother-of-pearl enhancer gives the product a pearly hue. It is added to a dry pigment in the form of a powder or to a tinting paste.

With sequins

Glitters are very often added to the ready-made epoxy solution - it is applied with a brush or an ornament is formed, carefully squeezing out of the glass with a thin stream. For a 3D effect, you can add glitter to finished products.

Optical colors for epoxy are considered a separate variety . They give the transparent composition an unobtrusive shade, combine well with pearlescent pigment, emphasizing the radiance of the tone. They can have a wide variety of shades.

Popular brands

In order to get the desired shade and economically use the material, it is better to give preference to the dyes of the same companies that released the epoxy at your disposal. The most popular products are Poly Max Dream and MG-Epox-Color . Usually they are sold in packs of 5-10 g, have a democratic cost.

On sale are colors of black, white, brown, blue, scarlet, green, as well as orange, purple and golden colors. The consumption of dyes from these manufacturers is low. To give a light transparent shade, the amount of pigment should not exceed 0.01–0.05% of the volume of the working composition.

To make the resin opaque, it is allowed to introduce 5% pigment - this volume is considered the maximum permissible.

What else can you tint the resin with?

Those who want to save money on the purchase of color schemes often use all kinds of improvised means for toning the resin. Such a solution cannot be called successful, since these components can enter into a chemical reaction with each other. Moreover, the price of dyes is low, and therefore, the savings will be small. Nevertheless, if you need to paint epoxy resin, and it is not possible to purchase a pigment for some reason, then it is worth adopting the following solutions.

- You can get ink from a gel pen - it provides a bright and predictable hue. But when using a ballpoint pen, the effect can be quite unexpected. For example, green ink produces a brownish tint.

- You can paint over the resin with paints for artists - it's better to use pastel oil paints, they give a bright saturated color.

- For painting in black, activated carbon is often used, as well as toner for the printer.

- The resin can be tinted with an alcohol-based stain.

- To give a whitish color to the resin, you can add baby powder, talcum powder, as well as tooth powder or white clay.

- Pharmacy greenery gives a rich green hue.

Coloring tips

In conclusion, we will give some tips that relate to the general requirements of working with epoxy

- Resin staining must be performed at a temperature of at least 22 degrees.

- When working with any epoxy compounds, it is recommended to use personal protective equipment (mask, respirator, gloves and goggles), work clothes must be with long sleeves.

- If resin or coloring pigment gets on the skin, immediately wipe the stain with a cotton pad moistened with alcohol, and then rinse with plenty of soap and water.

- If the work is carried out indoors, it is important to provide for good ventilation or the possibility of ventilation.

Accurate adherence to all recommendations will allow you to perform ideal painting at home and at the same time not harm your health.

Recommended:

OSB Painting (41 Photos): What Paint To Paint The Plates? Primer Paint For OSB Panels, Rubber And Other Types. How Beautiful Can You Paint OSB Sheets?

How is OSB painting carried out? What paint to paint the slabs? Primer paint for OSB panels, rubber and other types - what are the characteristics, which one to choose? How beautiful can you paint OSB sheets? Overview of manufacturers of cladding products. OSB panels painting technology, several recommendations

Furniture Made Of Epoxy Resin (51 Photos): Kitchen Facades Made Of Wood And Epoxy, A Chair And Doors, A Window Sill And A Bar Counter, Shelves And Other Products Made Of Furniture Epoxy

Furniture made of epoxy resin is a new development of designers, which has high decorative and technical characteristics. Features of these structures. What types of polymer furniture are there? Design options for kitchen facades made of wood and epoxy, chairs, doors, window sills. Bar counter made of polymer. Decor of products. Beautiful examples

Epoxy Resin Fixtures: Wood And Epoxy Resin Lamps And Nightlights. Can LEDs Be Filled With Epoxy Resin?

Epoxy resin fixtures are beautiful and distinctive. How to make lamps and nightlights out of wood and epoxy with your own hands? What other types of lamps are made of this material? What needs to be prepared for pouring the mold with epoxy resin?

Black Gladioli (22 Photos): Description Of The "Black Prince" And "Black Velvet", "Black Velvet" And "Black Cardinal", "Black Crow" And Other Varieties

Black gladioli: names and descriptions of popular varieties. Sorts "Black Prince", "Black Velvet", "Black Velvet", "Black Stone", "Black Raven", "Black Atom" and others. Basic rules for the care of gladioli

How To Make Glowing Paint? Do-it-yourself Phosphor Paint Without Phosphor, How To Make A Glow-in-the-dark Coloring Composition At Home

Glowing paint can be used both in construction and in creativity. Do-it-yourself phosphoric paint without phosphor can be made at home. How to make glowing paint?