2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

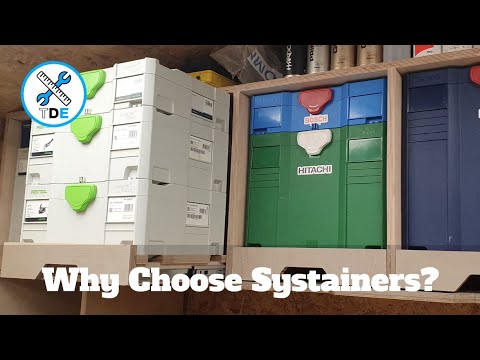

Systainers are modular universal boxes designed for systematically ordered storage of items, used to perform various jobs.

These storage boxes are used by organizations with a range of tasks that require the movement of a large number of items and tools in an orderly manner. Special purpose vehicles are equipped with Systainers: ambulances, fire trucks and others.

Boxes vary in size, material and appearance. The leading Systainer companies are Tanos, Makita, Magnusson.

Peculiarities

Such products is divided into 4 types:

- as large as possible;

- medium;

- mini boxes;

- micro-systainers (promotional and gift modifications).

Each type of Systainer is adapted to be used together with other similar drawers. Their dimensional parameters have values that allow you to organically combine blocks in the desired combination.

Each drawer is equipped with a set of special clips . They serve as locks for the box itself and fasteners that allow you to connect it to others. In the framework of joint use, one unit can be installed on top of others or in a side abutment position. Compatibility of devices of different sizes and brands in one bundle is allowed, if the location and characteristics of the fixing points allow it.

The latest models are equipped with special twist locks that replace clip connections. This technical solution makes the block connection procedure simpler and increases the service life of the fasteners. The new type of locks give access to the elements of the Systainer system, located in the middle or lower position. Access is achieved by turning the lock to a specific position, which attaches the lid of the lower box to the bottom of the higher box. In this case, the lid of the desired box is detached from its own block. This technology makes it possible to simultaneously operate all Systainers in a connected position.

For efficient separate transport, the units are equipped with a handle located at the top of the housing . The handle is a structural element reinforced with stiffening ribs and installed in such a way that at the time of movement the drawer is in the most level position. Some models have side recesses, which are grooves for holding the drawer with two hands.

To facilitate the movement of several connected Systainers, blocks with wheels are provided. They are installed in the lower part of the structure. Movement is carried out by holding the prefabricated storage system by the handle of the upper element. The final form is a two-wheeled cart containing several boxes.

Blocks are made mainly of durable plastic, reinforced with ribs of various configurations . Depending on the manufacturer and the specific model line, the boxes can be made in one color or another.

Self-production

As an alternative to the branded Systainer, you can construct its analogue of your own production. This will require the following materials and parts:

- plywood sheets in the right amount (depending on the size of the product);

- fasteners (corners, ties, plates);

- wooden blocks with different dimensional parameters;

- groove blocks - systems that allow you to store items in a fixed form;

- self-tapping screws / screws and other threaded fasteners.

List of tools:

- electric or manual jigsaw;

- drill and screwdriver (screwdriver);

- Bulgarian (impeller);

- drills, nozzle bits and other accessories;

- measuring tool (tape measure or ruler);

- workbench or other work place that has a flat surface.

Manufacturing process

Before starting the assembly of the product, detailed drawings should be prepared containing instructions for the dimensions of certain parts of the structure.

The algorithm of actions is as follows

- Parts procurement . Cut out elements from plywood that will be used as walls and partitions (if any). All side walls must match in pairs in terms of dimensional characteristics. Any deviation in this area can lead to a violation of the geometric shape of the product and loss of its strength.

- Cut out details from slats , which will correspond to the lengths of the corners of the future box. They will be placed inside each inner corner of the block. This will allow for a more reliable bond between the walls.

- Connect with each other prepared parts as shown in photo 2. Workpieces from laths are screwed along the perimeter of the inner corners. In order to avoid cracking of wooden elements due to screwing in self-tapping screws, it is advisable to drill mounting holes with a smaller diameter. So that the screw heads do not protrude above the surface of the body, a secret recess is drilled with a diameter equal to the diameter of the screw head.

- The resulting block is fastened with metal corners , screeds or plates. The presence of these fasteners and their location on the body will be determined by the specific design features of the homemade Systainer.

- Prepare and attach the plywood bottom . Strengthening the strength of this part of the product should be given some time. At the time of loading the container with storage items, the load factor on the points of contact between the bottom and walls of the product will increase.

- Equip the lid . This part is similar to the bottom, but has some structural differences. The lid is equipped with hinges, the presence of which can provide for special seating spaces that affect the appearance and geometric shape of the element. In the central part of the lid there is a handle for opening the box and carrying it. Its attachment points, like the hinge attachment points, must have a high level of strength, since they take on a larger percentage of the weight load.

- Lock device . It is necessary to equip the box with a locking device that will hold the lid closed during transport and can withstand the permissible loads. A latch and similar devices can be used as a lock.

The drawer can be equipped with support legs, ventilation holes, side handles and other necessary additions.

Advantages and disadvantages

Homemade Systainer has a low cost compared to the store equivalent. It can be designed in such a way that it best suits the requirements of a particular user. The shape and structure of the box can be adapted for use in certain conditions. These are the advantages of a homemade product.

The disadvantage of such a box is its low ergonomics when compared with factory models.

It is very difficult to make fastenings with your own hands that allow you to connect the boxes of boxes to each other and other parts of the structure that require the use of a high-precision tool.

Regardless of the production method, Systainers are the best way to store tools and other items that need to be organized. They allow you to sort items by size, functional purpose, to ensure their compact arrangement in the allotted space, as well as the best preservation.

Recommended:

Split Systems Rating: The Best Cheap And Elite Split Systems For Apartments In 2021. Top Manufacturers In Terms Of Price And Quality

What are the criteria for choosing a split system? Which brands are the best manufacturers of household air conditioners in the world? Split systems rating: the best cheap and luxury split systems for an apartment

Mini-split Systems: Selection And Manufacturers Of The Most Compact Split Systems With A Narrow Internal Block For An Apartment

Mini-split systems are perfect for creating a comfortable microclimate in small spaces. Description and characteristics of such devices, the choice and manufacturers of the most compact split systems with a narrow internal block for an apartment - read about all this in the article

Sanded Plywood (13 Photos): How Is It Different From Unsanded Plywood? Premium Grade Plywood Sanded On Both Sides And Other Options

The article describes what sanded plywood is, how it differs from unsanded plywood and what it is used for

Festool Systainers: Dimensions And Drawings. Mini Systainers And Their Compatibility

What is a Systainer? How do Festool Systainers differ from other options for storing and transporting instruments? What are the standard sizes for these items? What do their blueprints look like? Are different models compatible? What is the compatibility of the mini-Systainers with the rest of the options?

Hyundai Music Center: H-MC180, H-MS260, H-MS240 And Other Micro Systems, Black And Mini Systems In Other Colors, Tips For Choosing Audio Systems

What is Hyundai Music Center? What are the features of the H-MC180, H-MS260, H-MS240 and other microsystems from this manufacturer? How to choose the right device for you?