2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

The three-phase generator is widely used in the private sector. Such generators have a capacity of 6, 10, 15 kW and above. This article describes the scheme and principle of operation of such devices, indicates their main differences and connection rules.

Device

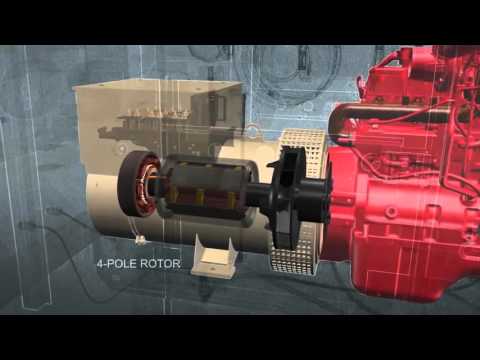

The purpose of an electric generator is to convert mechanical energy into electrical energy. It consists of 2 main parts - a moving rotor and a fixed stator.

- The rotor is mounted on bearings … On the one hand, a drive from an external source of motion is connected to it, and on the other, an impeller for cooling.

- Stator - fixed element … It contains the mounting feet of the unit, cooling fins and output terminals. And also a plate with technical characteristics.

Other components

- Rotor sliding contact. It is necessary to power its windings or to drain the generated electricity. Most models do not have it.

- Indicator and control means.

- Side covers.

- Oilers for supplying grease to bearings and other equally important elements.

Now you need to understand the method of obtaining electricity.

Principle of operation

Operating principle of three-phase generators based on the law of electromagnetic induction . It reads: an electromotive force (EMF) will be induced at the ends of a metal frame placed in a rotating magnetic field . In this case, both the frame itself and the magnets can rotate.

This is how demo models work. In real generators, instead of a frame, a coil of thin copper wire with conductors isolated from each other is used. This is done to increase the efficiency of the installation.

This is how a single-phase generator works. To obtain a 3-phase current, the windings must be 3. At the same time, they are located in a circle, and the angle between them (it is called the phase shift angle) is 120 degrees.

In modern models of 3-phase generators, the rotor acts as a magnet. In this case, the magnet can be permanent or electric. In the latter case, a sliding contact with graphite brushes is used to power the rotor. To start such a device, a separate source of electricity is needed.

The power winding is located in the stator. This removes the need to transfer large currents through the sliding contact and increases operational reliability.

Advantages and disadvantages

3-phase alternators have a number of advantages

- Higher efficiency compared to single phase . This means that less fuel is required to obtain the same current output.

- From one generator it is possible to obtain 2 voltage values that differ by a factor of 1.75 . Usually it is 380 V and 220 V. This expands the scope of its application, such a generator can be used both in a private house and in industry.

- With the same power, they have smaller overall dimensions and weight than single-phase .

- To transmit 3-phase current, 3 or 4 wires are needed . For the operation of 3 single-phase generators of wires, a minimum of 6 is required.

- Higher installation reliability .

- Most industrial equipment needs exactly 3-phase current to operate .… The use of such a generator solves this problem.

- To obtain a single-phase voltage, only 1 winding can be connected . But this is not the best solution in terms of economy.

- From alternating current, using a rectifier, you can make constant .

Such generators also have disadvantages

- The relative complexity of the connection from a legal point of view . For the legal connection of 3-phase voltage, a special permit from the power company is required. And getting it is very troublesome.

- Security measures need to be strengthened . More protection devices are needed, an RCD must be installed on each phase.

- It is not recommended to leave a running generator unattended .… It is necessary to monitor the readings of the instrumentation.

- Noise and vibration when the device is running.

Views

3-phase alternators are not very different from each other. They differ only in power and design features.

According to the power of the generated current, they are:

- 5 kW;

- 6 kW;

- 10 kW;

- 12 kW;

- 15 kW or more.

I must say that this is a standard power range, and it is not absolute. Manufacturers can produce machines with other characteristics.

In addition, the actual power output depends on many factors, such as the quality and purity of the fuel, the state of the atmosphere (in the cold and with high humidity, the power decreases), and the like.

By the type of fuel used, generators are:

- diesel;

- gasoline;

- working on wood or natural gas.

The most widespread are the first 2 options. Wherein diesel, by virtue of their design, are more reliable , because they work without an ignition system. They are also more economical. Gasoline, in turn, start easier in difficult conditions.

Gas models are not as efficient in private use, and therefore less common.

According to the principle of operation, generators are synchronous and asynchronous

Synchronous . Their advantage is that they can withstand a short-term overload of 5-6 times. This happens when starting some types of electric motors and other powerful equipment, when the starting currents are significantly higher than the rated ones. But they have drawbacks - these are large dimensions and weight, as well as less reliability compared to their asynchronous counterparts.

Asynchronous . Their main features are lightness, compactness, simplicity of design and trouble-free operation. But they immediately fail when overloaded. Therefore, the maximum power generated by them should be significantly higher than that consumed by consumers (3 - 4 times). In addition, it is recommended to install high-quality and expensive overload protection.

Also, generators can have additional functions:

- the ability to connect additional lines to increase the load capacity;

- adjustment of the characteristics of the output current (for example, its shape);

- the presence of an electromagnetic relay-regulator.

By design, generators are:

- basic;

- auxiliary.

They differ only in the way they are connected.

That's all for the classification of generators. Now let's talk about choosing this device.

How to choose?

When buying, first of all, be guided by the conditions in which the generator will operate

- First, determine the required power … It must exceed the total power of simultaneously switched on consumers. It is recommended that you have a small (or large) supply in case of emergencies.

- Select the type of fuel . Decide which is more important to you - economy or the ability to run in any conditions.

- If overloads are possible on the network, you need to buy a synchronous model . But keep in mind that it will require more thorough maintenance than asynchronous and has a shorter lifespan. And you will have to spend money on the protection system. If overloads are completely eliminated, an asynchronous generator is the best choice.

Then check the workmanship

- Turn the rotor by hand . It should rotate easily. No crunching, clicks or jerking in the bearings, as well as the runout of the rotor. It should not wobble in the bearings.

- Contacts and terminals must be shiny … Stripped threads are not allowed. If there are wires, reliable insulation is required. Especially at joints and bends.

- The stator and frame must be free of cracks . Examine the support carefully.

- Check the generator in operation … The readings of the measuring equipment must be stable. The exhaust sound must be even.

- Responsible manufacturers paint the product carefully and attach the logo well . If the paint is in doubt, it is better to refuse such a generator.

- The solidity of any company is determined by the quality of service . Make sure that when a malfunction occurs, you can find a specialist to fix it.

Then take a look at the additional features

- It is good if the measuring devices are already installed at the factory.

- It is better to buy models that have both a manual start and a starter.

- Check for ease of transportation. If there are casters, they should spin well. If there are handles, they should be comfortable to hold.

And do not be afraid to ask questions to consultants, even, in their opinion, ridiculous. The time that you spend on the choice is more than compensated for by trouble-free operation.

But it is not enough to choose a good generator, it still needs to be connected correctly.

Connection diagrams

The main task when connecting to the existing power grid is prevent the "meeting" of the generated current and the one coming from the power plant . Otherwise, the consequences will be dire.

To solve this problem, there are several methods for connecting the generator to the mains.

Through an outlet

The easiest method. Consumers are connected directly to the generator. But there are serious disadvantages:

- complete absence of protective devices;

- you need to buy a special 4-pole outlet, designed for high current.

This method is strongly discouraged. We wrote about him only because he exists.

Through the distributor machine

This is a more convenient method as it does not require any changes to the existing electrical network. It has proven itself especially well in private homes.

Follow the steps below to connect

- Switch off the input circuit breaker of the centralized power distribution system. Simply put, de-energize the house.

- Install a new 4-pole circuit breaker in the panel. Connect its output contacts to the home network.

- Carefully connect the generator cable to the new machine. All wires are connected to the corresponding terminals.

The 4th pole is needed for the neutral wire.

Through the switch

The main disadvantage of the previous scheme is the possibility of mains voltage entering the generator. This can happen if the switches are not used carefully. To prevent this from happening, the generator can be connected through a switch.

Such a connection completely eliminates the possibility of a short circuit. The switch has 3 contacts:

- first - food for consumers from a centralized network;

- the third - power supply from the generator;

- central - the network is completely de-energized.

Consumers are connected to the central contact.

After the switch, fuses, RCDs and other protective equipment must be installed.

In this way, the main generators are connected.

Automatic activation system

The main disadvantage of all these methods is manual control. And sometimes it is necessary for the generator to start automatically (especially in emergency situations) . In these cases, an automatic activation system is used.

It includes 2 cross starters and a control module. In the event of a power outage, they disconnect consumers from the centralized system and connect to a generator.

Regardless of the connection method, never forget to ground the generator frame. And most importantly: switching devices, switches and fuses must not be placed in the ground wire . This will prevent accidents and guarantee the safe operation of the device.

Recommended:

ATS For The Generator: Connection Diagrams Of The Block With Generator Autostart. What Is It And What Does The Controller Consist Of?

ATS for a generator: what it is, what it is and how to choose a high-quality solution for a stable power supply. Wiring diagrams of the block with autostart of the generator of various types

Electric Generator (52 Photos): The Principle Of Operation Of An Electric Current Generator, Types, What It Consists Of And How To Choose

What is an electric generator, what does it consist of and how to choose? What types of devices are there, what is the principle of operation of an electric current generator, which companies supply such equipment? History of its creation

Synchronous Generator: Principle Of Operation, Idling Characteristics And Device, Parallel Operation. How Fast Does The Rotor Spin?

A synchronous generator is a device for generating alternating current. It is worthwhile to study in more detail the principle of operation of the unit, idling characteristics and the possibility of organizing parallel operation

Gasoline Generators For Home: How To Choose An Electric Current Gas Generator For A Private House? Connection Diagram Of The Gas Generator To The Network

Gasoline generators are considered the best solution for a private home. How to choose an electric current gas generator, connect it? Rating of the most popular models

Microphone: What Is It? How To Choose? Characteristics And Device, Purpose And Principle Of Operation Of The Microphone, Diagram. What Is It For And What Does It Consist Of?

Microphone - what is it, what is the purpose, device and principle of operation of the microphone? What are its characteristics? How to choose the right microphone?