2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

The choice in favor of solid beech furniture boards is made today by many craftsmen engaged in woodworking, making home furnishings. This decision is due to the excellent characteristics of the material, the absence of defects, and an attractive appearance. All-laminated and spliced beech boards with a thickness of 20-30 mm, 40 mm and other sizes are used in furniture production, interior design, and are suitable for creating window sills and stair treads.

Peculiarities

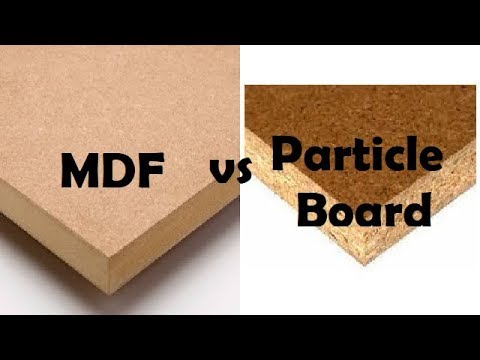

Eco-friendly and safe solid wood materials are superior in all respects to boards made from shavings, sawdust or wood chips. Beech furniture boards are obtained by pressing and gluing individual lamellas - boards or bars obtained by sawing a log . The production technology of the material has been known for over 100 years and is used everywhere. The finished panels have a rectangular or square shape, in width and length they are produced in a more convenient format than standard sawn timber and slabs obtained by radial sawing of wood.

In the process of manufacturing a furniture board, a careful rejection of defective areas takes place. Knots and rot are removed, cracked places are cut out.

By this, the shield compares favorably with the array - it is devoid of flaws, has a surface that is impeccable in its structure and texture. There are other features of this type of wood panel.

- Attractive texture . She does not need decorative finishing.

- Uniform color . In the process of assembling the furniture board, beech lamellas are carefully selected according to shades. This makes it possible to maintain the natural tone of the material without changing it.

- Long service life . Finished products are capable of retaining their original properties for 30-40 years.

- Stable geometric parameters . Bonding the lamellas in length and width under pressure ensures that the dimensions of the board remain constant. It does not shrink, warping is excluded. That is why the material is often used for the manufacture of door leaves.

- Resistant to wear and tear . In terms of strength, beech is practically not inferior to oak. Dense wood is not afraid of mechanical stress, friction, and does not absorb moisture well.

- Environmental friendliness . Used joinery adhesives do not contain harmful and hazardous substances, ready-made boards can be used even in bedrooms and children's rooms.

- Affordable cost . Spliced parts are cheaper than solid wood counterparts.

The surface of the beech furniture board is perfectly smooth and well finished. When glued correctly, it is almost impossible to notice the seam areas.

The entire panel looks like a single product, which adds to its visual appeal.

At the same time, the material is easy to cut, curly cutting . It is possible to cut out details and elements of complex shape from it.

Applications

The use of beech furniture boards is mainly associated with the production of structures for home use

- Cloths of interior doors . The furniture board allows you to obtain a product with precise dimensions and geometric parameters.

- Details of the flooring, ceiling . This includes panels of different thicknesses, depending on the design loads.

- Parts of ladder structures . Steps, platforms, railings are durable and resistant to wear.

- Kitchen countertops, bar counters . The high density of wood makes them resistant to wear and moisture.

- Window sills . It is possible to produce a variant of a non-standard size with high strength characteristics.

- Cabinet furniture . It can be manufactured in various configurations. The shield goes both to the frames and to the front part.

In addition, large-format panels can be used to decorate the walls in today's fashionable eco-friendly design, country style, loft.

Views

The furniture board made of solid beech is produced in several standard sizes. The minimum thickness is 16 mm, the maximum is 40 mm. For the manufacture of furniture structures with a low load, panels of 20 mm are taken, for shelves and floors - 30 mm . Standard widths are 30-90 cm, length can reach 3 m.

All products are divided into 2 large categories. They may be whole lamellas - consisting of strips corresponding to the length of the backboard. This option allows you to achieve an exact resemblance to solid wood. The solid-plate version looks more presentable, the connection occurs only in width.

Spliced the shield is assembled by pressing and gluing short lamellas no more than 60 cm each, which noticeably affects the uniformity of the front surface.

Nuances of choice

When choosing a furniture board made of beech wood for your own furniture production or interior decoration, it is important to pay attention to some important factors

- Humidity level . For glued timber, indicators up to 12% are considered the norm. High humidity indicates a violation of storage conditions. A fungus can develop inside such material, while visible manifestations will not appear immediately.

- General state . Rather strict quality standards are set for the furniture board. The presence of knots, cracks, areas that differ greatly in color indicate a low grade of products. In addition, there should be no traces of clearly mechanical damage, mold and rot.

- Cut type . It can be tangential - with a pronounced wood pattern that lends itself well to mechanical processing. There are also options from radially sawn material. In this case, the product will have a more uniform structure, high strength and stability of characteristics.

- Class . The best furniture boards made of beech are classified as A / A, the raw materials for them are selected by hand, sanded to a perfect smoothness. Grade B / B implies gluing lamellas, small knots are allowed in a small amount. Grade A / B assumes that the front and the bottom are of different quality. Grinding is not performed from the inside out, defects may be present, which greatly reduces the value of the material.

When choosing beech furniture boards, it is important to pay attention to all these parameters. Together, they will help you choose a product that meets all your requirements.

Care Tips

There are certain rules that can significantly extend the life of the furniture board and products from it. The main care products are oil impregnations and polishes. It is recommended that coverage be renewed annually. In this case, the surface of the wood will be reliably protected from moisture, defects and chips will not appear on it.

In addition, it will be useful to adhere to the following recommendations:

- operate and store products only in rooms with normal humidity levels, without sudden temperature changes;

- avoid placing a furniture board in the immediate vicinity of lighting sources, radiators, heaters;

- protect the surface from mold and mildew with the help of special compounds;

- carry out cleaning and cleaning only with soft compounds without abrasive particles;

- avoid shock loads on the wood surface.

If chips or other defects appear, the furniture board can be restored . It is enough to prepare a paste based on small sawdust and PVA glue or similar in composition, fill up the irregularities, and then grind the problem area.

Recommended:

Birch Furniture (54 Photos): Solid Wood Kitchens And Others. Is It Better Than Beech Furniture? Color Of Birch Tables And Cribs, Dressers And Other Furniture

Solid birch furniture: features, advantages and disadvantages. Is it better than beech furniture? Kitchens and sets for children's rooms, other furniture. The nuances of choice. Care Tips

Furniture Made Of Epoxy Resin (51 Photos): Kitchen Facades Made Of Wood And Epoxy, A Chair And Doors, A Window Sill And A Bar Counter, Shelves And Other Products Made Of Furniture Epoxy

Furniture made of epoxy resin is a new development of designers, which has high decorative and technical characteristics. Features of these structures. What types of polymer furniture are there? Design options for kitchen facades made of wood and epoxy, chairs, doors, window sills. Bar counter made of polymer. Decor of products. Beautiful examples

Garden Furniture Made Of Wood (82 Photos): Wooden Products From A Log For A Summer Residence, A Set Of Country Furniture Made Of Metal And Solid Wood

Garden furniture made of wood will be an excellent decoration for your personal plot. How to create compositions correctly using wooden products from a log for a summer residence? What are the advantages of wood?

Beech Furniture: "light Beech" And Other Colors Of Solid Wood Furniture, Pros And Cons, Children's Furniture Made Of Material And Others. Is Beech Better Than Pine?

Beech furniture, what are the advantages and disadvantages of it? Light beech, and other colors of solid wood furniture, how do they differ? How to properly care for such furniture? What should be considered when choosing beech furniture? What is the difference between beech garden furniture?

Furniture Boards Made Of Pine: 18-28 Mm And 40 Mm, Other Sizes, Pine Boards Made Of Solid Wood And Glued, Their Production And Painting

What are pine furniture boards, 18-28 mm and 40 mm, other sizes. Solid pine panels and glued options - where and how can they be used?