2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

Profiled iron products are widely used in various areas of construction, as well as in the construction of residential premises. C9 corrugated board is a profile for walls, but it can also be used as a product for installing roofs.

Description and scope

C9 profiled sheet can have two types of coating - zinc and decorative polymer. Painted corrugated board C9 is available for sale in all kinds of shades. All of them are indicated in RAL - the system of accepted colors. The polymer coating can be applied on one or both sides at once. In this case, the surface without painting is often covered with an additional layer of transparent enamel.

The C9 is manufactured from cold rolled zinc plated steel . This is exactly what is spelled out in GOST R 52246-2004.

In accordance with the technical regulations for the product, the dimensions of the profile must meet the requirements of GOST and TU.

The C9 product is used for:

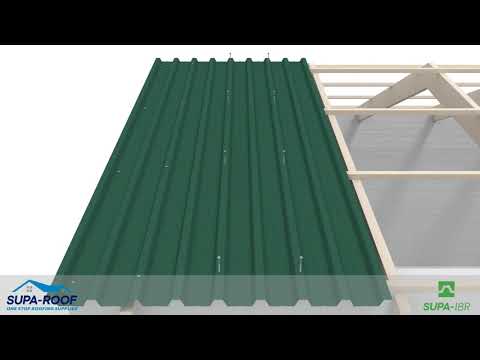

- arrangement of a roof with a slope of more than 15 °, when there is a solid lathing or a step from 0.3 m to 0.5 m, but the angle increases to 30 °;

- design of prefabricated houses and structures, pavilions for trade, car garages, warehouse premises;

- creation of all kinds of frame-type structures;

- erection of panel systems, from which fences are made, including fences;

- insulation of wall partitions and the buildings themselves;

- reconstruction of structures;

- construction of sandwich panels at an industrial level;

- designs of false ceilings of any configuration.

How is a professional sheet made?

Profile sheet is steel in a roll, the plane of which, after processing on special machines, has a wavy or corrugated shape. The task of this operation is to increase the longitudinal rigidity of the structure . Thanks to this, even a small thickness allows the material to be used in construction, especially where dynamic and static loads take place.

The sheet material undergoes a rolling process.

Specifications

Product marking is necessary to indicate the main properties of the described profile. The dimensions are also indicated there, including the width.

For example, professional sheet C-9-1140-0, 7 is deciphered as follows:

- the first letter indicates the main purpose of the product, in our case it is a wall profile;

- number 9 means the height of the bent profile;

- the next digit indicates the width;

- at the end, the thickness of the sheet material is prescribed.

Species overview

The described product can be of 2 types

- Galvanized . It is characterized by the presence of an anti-corrosion coating on the surface. Manufactured from sheet steel.

- Colored . In this version, a primer is first applied, then a zinc coating and only after that a decorative layer. The latter can be polyester, polymer textured coating or Pural.

Tips for mounting sheets

The protective layer can significantly increase the life of the product. Under normal conditions, the service life of a profile of this class is 30 years. Due to its low weight, the material is widely used in the construction industry. It can be used for non-removable formwork as well as frame systems.

- Before using corrugated board as a material for the roof, you will need to correctly make the crate.

- A vapor barrier must be installed, but a gap is left for ventilation. Then the lathing is installed and then the building material.

- Since the crate is made of timber, additional processing from moisture and mold will be required. A building antiseptic is suitable for this.

- When using the C9 profiled sheet, it is necessary to take into account its features. As a material for construction, it is one of the most affordable options for roofing and walls today.

Ease and ease of use of the profile guarantee a high-quality work in the end.

The minimum weight makes it easy to transport the sheets for roofing . Just two people are enough to create an attractive roof for any architecture.

It is the long service life and reasonable price that allowed increasing consumer demand for the described product. In addition, manufacturers offer a wide range of color palettes.

Recommended:

Profiled Sheeting MP20 (34 Photos): Dimensions Of Profiled Sheets, Technical Characteristics Of Galvanized Sheets For Roof And Fence, Lathing Step

What is professional flooring MP20, what are the dimensions of professional sheets? What are the technical characteristics of galvanized roof and fence sheets? What types of coatings are applied to them, and how is the installation carried out?

Profiled Sheeting НС35 (26 Photos): Dimensions Of Profiled Sheets And Technical Characteristics, Lathing Step. Weight Of 1 M2 Of Galvanized Profiled Sheet, Choice Of Sealant

What is HC35 professional flooring? What are the basic dimensions of profiled sheets and their technical characteristics? What can be the step of the lathing? What is the weight of 1 m2 of galvanized profiled sheet? How is the seal selected?

C44 Profiled Sheet: Dimensions, Weight And Other Technical Characteristics In Accordance With GOST, Galvanized Profiled Sheeting And Other Types Of Profiled Sheet

What is professional sheet C44? What are its dimensions, weight and other technical characteristics in accordance with GOST? How to choose the right material and where can it be used?

C15 Profiled Sheet: Dimensions And Other Technical Characteristics, Self-tapping Screws For Profiled Sheet. Corrugated Sheets, Wood Grain And Others

What is C15 professional sheet? What are its dimensions and other technical characteristics of corrugated sheets? What self-tapping screws should be used for the C15 profiled sheet and how to install it correctly?

Profiled Sheeting C18: Dimensions And Other Technical Characteristics, Profiled Sheet In Graphite Color And Other Colors

What is C18 corrugated board? What are its main dimensions and other technical characteristics? What you need to know about the profiled sheet of graphite color and other colors, what consumers need to know?