2024 Author: Beatrice Philips | [email protected]. Last modified: 2023-12-16 05:33

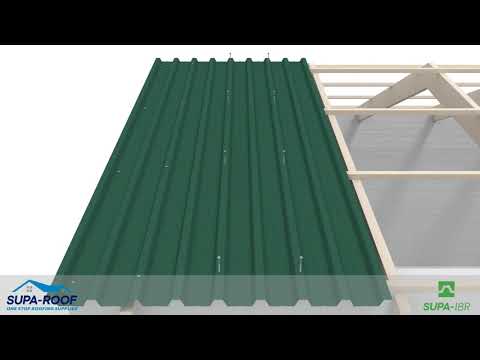

Everyone preparing for the construction and repair of their home or other object needs to carefully study the features of C44 profiled sheets. Their size, weight and other technical characteristics in accordance with GOST play a significant role. And you should also study the difference between galvanized corrugated board and other types of professional sheet.

What is it and how is it done?

Decking, including profiled sheet C44, is made from steel obtained in accordance with GOST 52146, adopted in 2003 . If rolled products are used in the form of a thin sheet, then it must comply with GOST 52246, in force since 2004. As for the process of processing profiles itself, it is built in accordance with the standard 24045, approved back in 1994. The letter C, as the standard 24045 indicates, predominantly means the wall use of the finished product. The difference between the individual sheet subtypes can be related to the characteristics of the protective coating.

Corrugation can significantly increase the mechanical strength of structures … The level of reliability is quite decent so that the C44 profiled sheet can be considered an attractive building material. There are no problems with the service life under normal conditions.

It should be noted that due to the insignificant height of the trapeziums, such a product is less versatile than products of the HC series. However, it can still be applied relatively broadly.

Stiffeners are placed on all waves of the metal sheet. They are located on both sides at once. That is why it is possible to give the structure a high mechanical strength. If the product meets the standard requirements, it can last up to half a century. Of course, if an additional condition is met - no deviations from the normal environment, no caustic and aggressive substances.

C44 products are also supported by:

- the convenience of carefully selected sizes;

- comparative ease (even the most ordinary people can lift a sheet);

- ease of installation;

- practicality.

The cost of sheets strongly depends on their thickness .… Anyway an anti-corrosion coating is applied to the finished product … The technologies of dyeing with a variety of dyes have also been developed. Taking into account the variety of colors, it is possible to provide a selection of shades for a wide variety of design concepts. The initial raw material for the production of profiled sheet is a thin (and even very thin) steel sheet. The shipment of such raw materials to rolling sites is always in rolls. This solution allows you to minimize the loss of cutting metal. The average roll weight is 7000-8000 kg. When a specially designed drum is twisted, the roll is unrolled, and the automatic unit transfers it gradually to the rolling mill. The size of the corrugation changes depending on the parameters of the rollers.

Cold roll forming keeps metal characteristics as efficient as possible … The final stage of production includes cutting to the exact size with guillotine-type scissors. Simple flat scissors, by definition, cannot cut metal smoothly enough. Then the time comes to stick on a special insulation tape (but not all manufacturers use it). Painting is usually done with a specially designed spray gun that is capable of spraying powder paint.

Specifications

The main parameters, of course, are reflected in the specialized GOST, which regulates the production of all corrugated board . But first of all, consumers are interested in completely different properties of the product. So, the dimensions of the finished products are quite standardized - the actually used (so-called working) width is 1000 mm. The total width, including unused parts, is 1047 mm by default.

The height of the profile corrugation is predictably 4.4 cm. The length of a single sheet ranges from 50 to 1450 cm, depending on the customer's request. In most cases, manufacturers have in their warehouses typical material 6 and 12 m long, which does not require preparation and fine-tuning. The accuracy of cutting into other sizes is 1 mm, which in practice is sufficient for any purpose. The weight of 1 m2 of a standard product ranges from 6, 9 to 8, 4 kg.

What are they?

Like roofing, sheet wall material can be:

- without special protection (extremely rare and impractical);

- hot-dip galvanized (the most massive industrial version);

- hot-dip galvanized and additionally covered with a protective and decorative mass (most attractive for private use).

Most often, they sell a professional sheet made of ordinary steel. It is not very resistant to corrosion, even though it has been specially treated. And yet, the cheapness, and at the same time the ease of use, do their job.

Arrangement with copper or aluminum sheet is much more expensive. By external design, profiles are distinguished:

- bent;

- with textured embossing;

- with special perforation.

To protect against adverse external factors, use:

- plastisol;

- polyester;

- pural;

- PVDF.

Nuances of choice

It should be said right away that there is almost no real difference between roofing, wall, fence and so on profiles . The fact is that in reality they flexibly interchangeable … It is the objective parameters that are decisive, not the formal type. For example, in the middle lane, where strong wind does not happen or rarely happens, where heavy snowfalls are unlikely, you can use the same C44 on a steep roof. However, it is best to consult with professionals.

The thickness of the metal can range from 0.4 to 1.2 mm. The higher it is, the greater the bearing capacity. But at the same time, the material itself becomes heavier, which increases the requirements for its fastening and supports. And the use of the heaviest options for roofing is not recommended for obvious reasons. In difficult cases, it is more correct to choose a material with a higher wave height than to increase the thickness.

The next topical point is what exactly the professional sheet is protected by. The most favorable price is zinc coating. However, it is not very durable . The service life does not exceed 25 years, and sometimes it is completely limited to 15 years if conditions are unfavorable. And yet, it is quite appropriate to use galvanized corrugated board to make temporary fences and form formwork; it is also suitable for a number of outbuildings.

Plastisol protection is much more practical and can last from 40 to 50 years. Sheets coated with aluzinc also serve the same time. In addition to the two main elements, their coating also includes binder silicon. Mainly, the profiled sheet with an aluzinc layer is used in the design of hangars and warehouses.

It serves the longest, but the polymer shell turns out to be more expensive than other options. But here it is also important to look at which specific polymer is used.

Polyester allows you to save money, and, moreover, is not afraid of rather strong heating . Even in difficult conditions, he will work honest 20-25 years. However, it is not difficult to scratch polyester or break it on impact. Pural tolerates mechanical forces much better. It will be able to maintain its basic qualities for up to 40 years, even with strong ultraviolet radiation. Plastisol, although formally tolerates wear better than pural, is not able to survive strong heat and bright sun.

Important recommendations:

- try to buy material directly from manufacturers;

- choose the most even, burr-free corrugated board;

- check the quality of the paint;

- require quality certificates;

- inspect several specimens randomly taken from a large batch;

- check the availability of the warranty and its validity period;

- take into account the reputation of traders.

Applications

As already mentioned, sometimes with the help of C44 they cover the roof. This material is suitable for both pitched and load-bearing roofs. Other possible options:

- decoration of facades;

- creating barriers around the construction site;

- the formation of formwork (both removable and non-separable type);

- partitions;

- wall covering from the inside;

- obtaining rigid diaphragms in frame structures;

- construction of permanent fences;

- sheathing of eaves overhangs.

Recommended:

Profiled Sheet Weight: How Much Does 1 M2 Of Profiled Sheeting Weigh 2-6 Meters? Weight Of One Square Sheet, Specific Gravity Of Painted Corrugated Board

Despite the small thickness - about 0.7-1 mm - the profiled sheet has a significant weight. One person cannot take it away, and not only because of the sharp edges that make it difficult to take it even with mittens . What does it depend on?

Profiled Sheeting MP20 (34 Photos): Dimensions Of Profiled Sheets, Technical Characteristics Of Galvanized Sheets For Roof And Fence, Lathing Step

What is professional flooring MP20, what are the dimensions of professional sheets? What are the technical characteristics of galvanized roof and fence sheets? What types of coatings are applied to them, and how is the installation carried out?

Profiled Sheeting C9: Dimensions Of The Profiled Sheet And Other Technical Characteristics. How Is A Professional Sheet Made? Types Of Sheets And Tips For Their Installation

What is c9 corrugated board. The dimensions of the profiled sheet and other technical characteristics. How a professional sheet is made. What features of installation should be considered when building a roof

Profiled Sheeting НС35 (26 Photos): Dimensions Of Profiled Sheets And Technical Characteristics, Lathing Step. Weight Of 1 M2 Of Galvanized Profiled Sheet, Choice Of Sealant

What is HC35 professional flooring? What are the basic dimensions of profiled sheets and their technical characteristics? What can be the step of the lathing? What is the weight of 1 m2 of galvanized profiled sheet? How is the seal selected?

Profiled Sheeting C18: Dimensions And Other Technical Characteristics, Profiled Sheet In Graphite Color And Other Colors

What is C18 corrugated board? What are its main dimensions and other technical characteristics? What you need to know about the profiled sheet of graphite color and other colors, what consumers need to know?