2024 Author: Beatrice Philips | [email protected]. Last modified: 2024-01-18 12:09

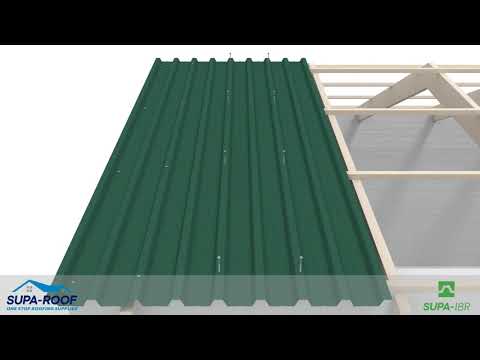

When planning to use a profiled sheet on the roof, the owner hopes that the roof will serve for many years. This usually happens, but much depends on the quality of the material and compliance with the rules for its installation.

Overlap calculation

Decking in the construction industry is becoming increasingly popular, confidently occupying a leading position in the public sector. There is a simple explanation for this - a profiled sheet roof is distinguished by its strength, durability, attractive appearance and affordable price.

The metal profiled sheet does not need special care, it is covered with an anti-corrosion compound, it perfectly resists the aggressive effects of the external environment - precipitation, winds and others. At the same time, it is very simple to work with it - it is quite lightweight and easy to install.

When working with corrugated board when organizing a roof from it, you must remember that certain conditions are met

-

The coefficient of overlap of profiled sheets when installing the roof of a house is determined by a regulatory document - GOST 24045 . Today there are 3 options: GOST 24045-86, GOST 24045-94 and GOST 24045-2010, and the latter has the current status. The first 2 have the status of "replaced", which is explained by the constant development of technology and changing building standards. Compliance with these guarantees reliable protection of the roof against moisture penetration. The overlap value depends on the ramp angle.

- Provided that the angle of inclination does not exceed 15º, the minimum overlap parameters are 20 cm . If you make an overlap with lower rates, then sooner or later this will manifest itself in the accumulation of moisture under the roof. Ideally, 2 waves are used for overlap, which will guarantee the reliability of the structure.

- When the angle is in the range of 15-30º , the size of the overlap is also increased to 30 cm - this is about 2 waves of the profiled sheet, which allows you not to think about measurements.

- If the angle of inclination exceeds 30-degree indicator , then an overlap of 10 to 15 centimeters will be quite enough. With this roof, tightness and strength, reliability and durability are ensured. For such indicators, one wave is sufficient, entering the pre-laid and fixed sheet.

If, when organizing roofing work, the method of horizontal laying of the roofing profiled sheet is chosen, which also happens, then the minimum indicator should be 20 centimeters. At the end of the installation activities, a silicone sealant is used to close the cracks in the formed overlaps . Calculations along the length and width of the material are carried out both for vertical stacking and for the horizontal method. The step rate depends entirely on the size of the selected sheets. Correct installation determines the duration of the roof and its reliability.

For reference: there are standards for the installation of the roof, consumption rates per 1 m2, which are described in SNiP.

Tips for stacking sheets

The roof installation technique involves several stages and the observance of mandatory conditions

-

Pre-installation of the waterproofing layer . Despite the fact that the profiled sheet is a material that absolutely does not allow moisture to pass through, when laying sheets and during operation, conditions may arise that favor moisture leakage under the roof. This is fraught with the accumulation of condensate, the formation of colonies of molds. That is why laying waterproofing material is an obligatory and necessary procedure. Its installation is carried out horizontally from the lower edge of the roof, observing the overlap of the strips by 10-15 cm. To ensure tightness, the joints are glued with adhesive tape.

- The organization of ventilation is mandatory, since moisture, although in a limited amount, still gets under the roof . Ventilation helps it evaporate and maintain dryness in the under-roof space. The best option is to waterproof the rafters at a height of up to 40-50 mm along the timber, which provides a gap between the insulating material and the crate.

Attention! Each part of the roof and roof made of wood must be treated with antiseptic compounds that prevent putrefactive decomposition of bacteria, mold and other factors.

Some experts recommend laying sheets from right to left on the roof . However, most experienced builders argue that this is the wrong approach. Laying is determined in accordance with the direction of the prevailing winds. That is, the joints are on the leeward side. This method creates additional protection measures against the penetration of rain and melt water under the joints during windy weather. For example, during installation, profiled sheets are laid from one side from left to right, and on the other, on the contrary, from right to left.

If the roof is so high that it exceeds the length of the corrugated board, then the installation is carried out in several rows, observing the direction from bottom to top. Therefore, the fastening of the sheets begins from the bottom row, after which it remains to make a transverse overlap - and continue laying the next rows . During the installation work on the flooring of the roofing profiled sheet, it is important to remember a common mistake - the initial skew of the laid sheets of the first row. If you start work without checking the building level with the horizon, then you can easily make a mistake and put the first sheet crooked. Because of this, all subsequent rows will go sideways, and the further, the stronger it will be noticeable - a so-called ladder will be formed. Attempts to correct the situation by shifting the sheets will lead to the formation of gaps.

Recommended:

The Working Size Of The Profiled Sheet: Width And Length. How To Determine The Working Width Of The Surface Of The Corrugated Board? What Is Roof Sheet Effective Area?

Why know the working size of the profiled sheet? Only with the help of the effective length and width will it be possible to determine the exact area of the material required for the purchase. It is worth figuring out how to calculate the surface area of the corrugated board

Installation Of A Profiled Sheet: Fastening To Metal Purlins And To Concrete. How To Properly Lay The Profiled Sheet? How To Fix The Corrugated Board On The Roof And Screw It On The Fence?

How is the installation of the profiled sheet carried out? How to lay the professional sheet correctly? How is it attached to metal girders and to concrete, what should you pay special attention to?

Dimensions Of Roof Sheeting: Length And Width Of Roofing Sheets, Standard Thickness Of Roof Sheeting. What Kind Of Corrugated Board Is Better To Take For The Roof Of The House?

Profiled sheet is the most suitable roofing material in terms of installation speed and quality. Thanks to galvanizing and painting, it can last 20-30 years before the roof does start to rust. Suitable sizes The optimal dimensions of the profiled sheet for the roof are the length and width of the sheet, its thickness.

Profiled Sheeting Grand Line: Colors Of Roofing Profiled Sheet, Options For Wood And Stone, Curly Profiled Sheet For The Roof And Others

What is so special about the Grand Line corrugated board? What are the colors of the roofing sheet? What are the options for wood and stone, what do you need to know about them?

C44 Profiled Sheet: Dimensions, Weight And Other Technical Characteristics In Accordance With GOST, Galvanized Profiled Sheeting And Other Types Of Profiled Sheet

What is professional sheet C44? What are its dimensions, weight and other technical characteristics in accordance with GOST? How to choose the right material and where can it be used?